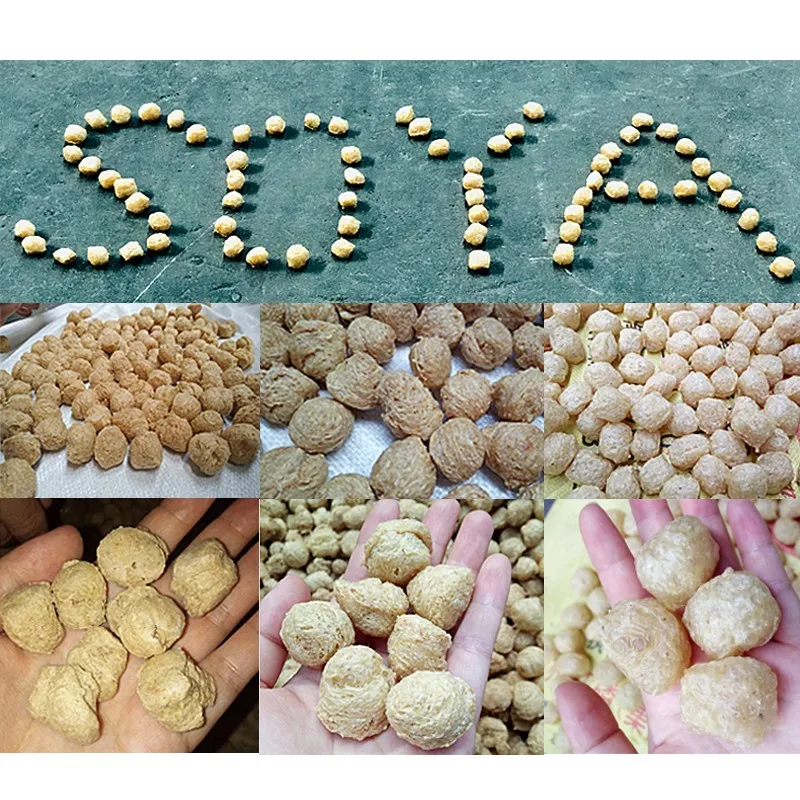

Successful installation of 1t/h soya protein nuggest making machine at Sujalpur,madhya Pradesh, India

Soya protein

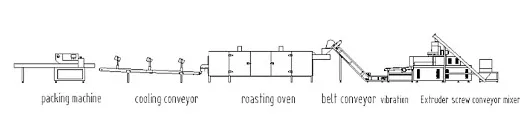

1.Process flow of soya bean protein production line

(Mixer----Scew conveyor---extruder--vibrating machine---dryer---cooling ---packing machine )

Detailed Image:

Blend Mixer

Motor: 3kw, 4kw, 7.5kw etc.

Capacity: 60kg/time, 100kg/time, 300kg/time, 500kg/time etc.

Material: stainless steel, carbon steel

Zhuoheng's Blend Mixer is a high standard two-way ribbon mixing machine. It includes material tank, screw mixing paddles and drive parts.

Double Screw Extruder

Motor: 22kw, 30kw, 55kw, 75kw etc.

Capacity: 120-150kg/h, 200-250kg/h, 300kg/h, 500kg/h, 1000kg/h etc.

Material: Screw materials 38CrMoAl

stainless steel, carbon steel

Soya protein extruder unit consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder, extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system, heating system, lubricating system and extraction steam system.

Dryer

Type: 5 layers 5 meters, 5 layers 7 meters, 5 layers 12meters, 7 layers 12 meters.

Heating source: electric, gas, steam, oil, diesel.

Material: stainless steel, carbon steel

Details----- Machine Main Features

Main Material: Stainless Steel(304/316)

Screw Quantity: 2Years

Screw Material: 38CrMoAl.

Rotating Speed: Adjustable

Temperature: Adjustable

Self-cleaning function

Forced gearbox lubrication system

Pasteurization function with high temperature and high pressure

Flexible collocation of equipment

Electric parts can be ABB, Delta, Fuji, Omron, Siemens; Famous brand as your demand