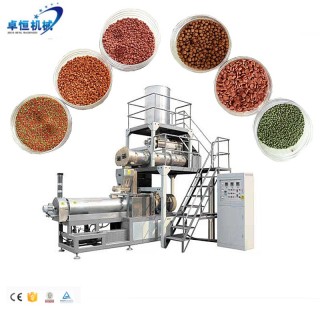

Fish feed pellet extruder animal food making machine production equipment

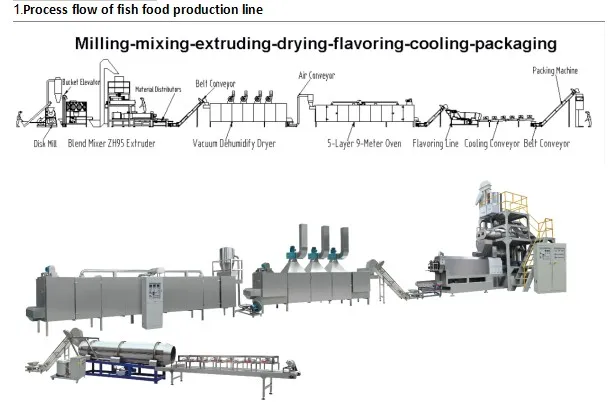

1.caoacity:100-120KG/H .200-250KG/H,500KH/H,1000 kg/h,2000kg/h ....5t/h

2.Siemens Motor

3.production diameter:2-15mm and different design

4.Energy:Electricity ,Diesel, Steam, Gas

Our pet food production line are applied to produce dog food ,cat food,fish feed and other allied animal food.Pet food manufacturing line can produce any pet food of textures,shape,size,flavors and color by the complete dog food machine line.

The charm of extrusion technology is that it can provide unexpected processing to people.It's researched and developed by Zhuoheng company combined the needs of kind of markets adopting unique processing technology and equipment configuration using grain flour,meat meal,fish meal,soybean meal etc as raw material to produce a varity of shapes of pet food and fish feed with special tastes and easy to digest,it is warmly welcomed in pet market.

Producing floating fish feed is exquisite tissue, beautiful shaped, reasonable nutritional structure. Because of floating long time on the surface of water, the feed is advantageous to the aquatic organisms so as to Effectively save floating feed quantity.

Floating/Sinking fish feed production line is the ideal of equipment for aquaculture farm proprietor. It is proved to have the advantages of high automation level, easy to operate, less occupied area, and maintenance accessibility.

This production line is consisting of Extrusion Forming System, Conveying System and Drying System,Cooling ststem with Professional design, reasonable configuration and the best quality products.

2.Final product of fish feed processing machine.

3.Detailed Image

Blend Mixer.

Motor: 3kw, 4kw, 7.5kw etc.

Capacity: 60kg/time, 100kg/time, 300kg/time, 500kg/time etc.

Material: stainless steel, carbon steel

Zhuoheng's Blend Mixer is a high standard two-way ribbon mixing machine. It includes material tank, screw mixing paddles and drive parts.

Double Screw Extruder

Motor: 22kw, 30kw, 55kw, 75kw etc.

Capacity: 120-150kg/h, 200-250kg/h, 300kg/h, 500kg/h, 1000kg/h etc.

Material: Screw materials 38CrMoAl

stainless steel, carbon steel

Fish feed extrudr unit consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder, extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system, heating system, lubricating system and extraction steam system.

Dryer

Type: 5 layers 5 meters, 5 layers 7 meters, 5 layers 12meters, 7 layers 12 meters.

Heating source: electric, gas, steam, oil, diesel.

Material: stainless steel, carbon steel

1. Heat With Infrared Ray Heating Tube, Raise And Lower Down Temperature Quickly, Small Heat Inertia And High Heat Efficiency.

2. Adjustable Transit Speed Of Net Belt With Accurate Temperature Control Device. Sliding Board Bottom Of Dryer For Easy Cleaning.

Hot Wind Cycle Device Makes Heating Energy Equally In The Dryer

3. Double-Roller Chain And Chain Drive Make Stable And Smooth Running

Single Drum Flavoring Line

Motor: 0.75kw, 1.1kw etc.

Capacity: 100kg-1000kg/h

Material: stainless steel

1.It's consist of hoistor, drum machine, flavoring machine and oil sprayer.

2. The oil sprayer sprinkle the atomized oil to the products in the drum.By continuous rolling material, the drum will make oil and seasoner evenly adhere to the surface of products. To prevent feed leakage, the hoister is used wavy baffle belt.

3. The oil sprayer can bear high temperature and pressure. Safe and durable. Mixing atomized oil and products evenly in the flavoring drum.

4. Inverter to adjust the speed of spices. Easy to control.

5. The drum drive run stably .No slipping no jumping.

The whole unit is reasonable allocation, simple operation; All materials mixing well, excellent quality.

Packing Machine

Type: automatic, semi-automatic.

Weight range: 1-5kg/bag, 5-25kg/bag, 25-50kg/bag

Material: stainless steel, carbon steel

1.The serious of electronic scale is net type,it using today's latest technology,suitable for packing irregular materials.such as:fish dog cat food.melon seeds.peanuts.lotus seed.walnut etc.

2.Feeding system adopts a bariety of ways:double door type vibration feeding,feeding size and blanking instantaneous stop.

Gurantee the packaging accuracy and speed effectively.

Jinan Zhuoheng Extrusion Machinery Co.,LTD established in 2008, has always been the professional manufacturer and the leader for advanced and high efficient extrusion food machinery in this field all over the world.

Our company has already exported countries:

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine.Poland }

North America { Canada }

South America { Brazil, Bolivia }

Oceania { New Zealand }

Russia kurstans Sweden

Pre-Sales Service: After-Sales Service:

* Provide the professional advice about the market, equipment, process, material, packing, etc.

* Assist you to choose equipment, design process flow, and perfect workshop layout. If needed, we can supply service in your factory.

* Make compensate plan to the material change according to your product, and perform the production at site.

* Specially design and manufacture machine, practice test, and provide relevant training as customer required.

* Provide reasonable packing and transportation plan, send technician to install, debug machine and train your workers.

* Two years guaranty time, preferentially supply spare parts.

* Design and process similar type of spare parts of import equipment.Related Products