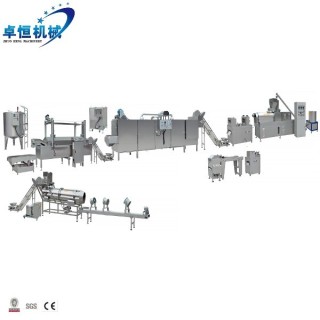

Various shape fried snack food machine

1. Our frying snack Food Extruder Manufacturers main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Fryer ,Dyer&Oven source can be designed use Electricity, Gas, Oil or stream.

6. Machine material generally is Food grade stainless steel, also can customized as require.

7. Guarantee Time is 2 year.

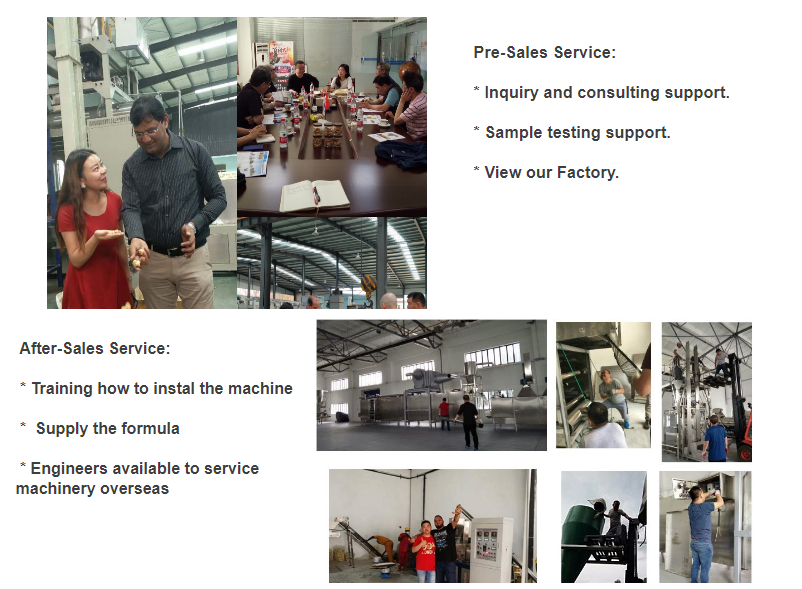

8. After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

9. Certificate: CE, SGS, BV

1.Product Description

Zhuoheng Frying sanck food production line are applied to produce various shapes popular in the market by changing molds and changing production processes with advanced extrusion technology.This line can finish automatically from feeding ,extrusion,frying,flavoring,packing.

The charm of extrusion technology is that it can provide unexpected processing to people.It's researched and developed by Zhuoheng company combined the needs of kind of markets adopting unique processing technology and equipment configuration using flour,corn flour ,rice flour ,corn starch etc as raw material to produce a varity of shapes of leisure time food with special tastes and easy to digest,it is warmly welcomed in food market.

1). All equipments are made of stainless steel.

2). The whole line fully continuous and automatic.

3). Zhuoheng provide basic formula according to your require.

4). The final food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the fish feed production line (depending on your require)

Regular Extruder ZH65 ZH70Capacity:120-150kg/h Application: snack food industry |

|

ZH85 |

|

/Tortilla Chips Shaper |  |

Dryer Type: Gas/diesel /Electric/steam |

|

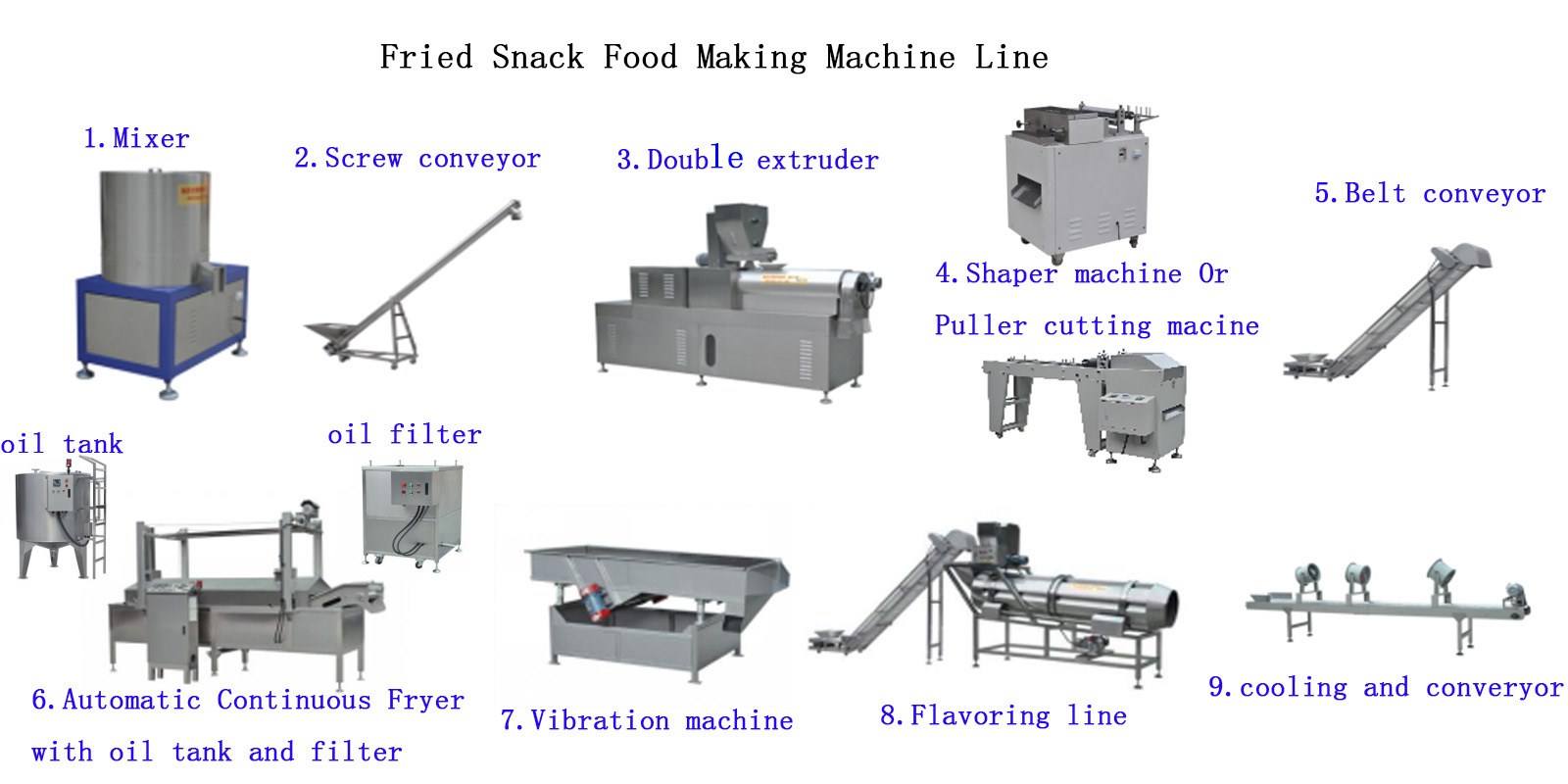

Automatic Continous frying system Including: Auto elevator’ Auto feeding belt Smart temperature system Smart Auto oil feeding system Material belt Continous shaking material belt |

|

Flavoring Including the oil sprayer,oil tank Belt conveyor and rotary machine. |  |

2.Processing line

| |

Mold (one line six sets for free) |  |

3.Fring snack samples made by our machines

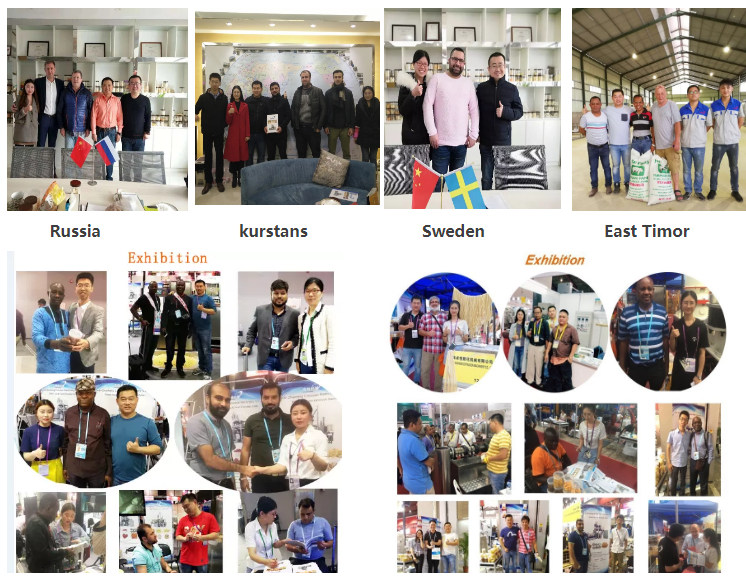

Our company has already exported countries:

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine.Poland,Sweden }

North America { Canada }

South America { Brazil, Bolivia }

Oceania { New Zealand }

Our Service

Packing and Loading