Full automatic Core-filling snack food machine procesing line

1.Core-filling food processing machine machine line uses advanced extrusion technology and achieve atomation from mixing ,extruion ,shaping,filling,drying,flavoring,cooling.

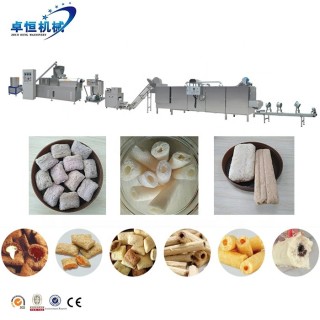

2.Snack food machine line can produce different shapes core-filling snack and puffed food by Chaning the molds.

3.This automatic process is of leading level for its superior characters"normal material,convenient operation and maintenance,lower powder consumption,higher output.

Ø This line can product various type core filled snacks by changing dies, such as pillows, stick, ball, etc

Ø The shape, size, flavor of snacks can be customized as requirement.

Ø Core filling machine fill the snacks with stuffing. The stuffing can be various.

Ø Baking and frying are available.

1. Production line details

210-250kg/h | |

Power Supply | Based on 380V 50 Hz 3 phase. Customized according to your local power. |

Machine details | 1.Stainless steel,:201, 304, 316, on request 2. Electric parts can be ABB, Delta, Fuji, Omron, siemens; Famous brand as your demand. |

Certificate | CE,GOST,TUV,BV, Supplier Assessment |

Raw Material | cereals (corn, wheat, oat, barley, rice …) whole grains and / or mixtures of grains |

Product Shape | Core filled Balls, Bars, Sticks, Pillows, tube, etc. |

Stuffing | Cream, Chocolate, Jam, Peanut butter ,etc. |

Formula | Providing basic formula. |

2.Advantages of core filling snack making machine

1. We specialize in high capacity extruder which can reach 250kg/h

2. The screw material: Alloy steel (38CrMoAL) by nitriding process. High strength and wear-resting.

3. Adopted the Delta inverters, ensure the extruder better running.

4. The gearbox has automatic lubrication function, which prolong service life of gears.

5. Cutting knife is fixed in the die head seat, rotary cutting driven by V-belt.

3.Technical Parameters

Installed power | Real power | Capacity | Dimension |

35 KW | 22kw | 120-150kg/h | 39000x1200x2200mm |

50kw | 37kw | 200-250kg/h | 41000x1500x2200mm |

4. Production process

Flour raw material mixing-extruding and shaping-Core filling-drying-flavoring-cooling-packing

5.Sample show

Jinan Zhuoheng Extrusion Machinery Co.,Ltd . A Shareholders-owned and operated business established more than 10 years ago, is considered as one of Chinese most respected and experienced suppliers of extrusion machine for fish feed ,pet food or other animal food.accessories and services,we also could support you other machine lines,like snack machine line,corn flakes machine line,macaroni machine line,etc.our company’s motto is :”Excellent Quality.Lasting Reputation”.

Pre-sale service | Communicating with customers and learn your requirement |

Providing professional advisory services | |

Providing solutions according to customers’ requirement,and offer the quotation | |

Providing on-site visit to our factory | |

Providing samples | |

Selling service | Confirm every terms and details and sign contract with customers |

Manufacturing machines according to contract. | |

Trial running after production. | |

Packing machines and delivery on time | |

Providing relevant documents for Custom clearanc (If necessary) | |

After-sale service | Send engineers for installation, trial running and trainingworkers. |

Handling the problems occurred during use. | |

Supply spare and wearing parts on discount. | |

Help customers to solve any other problems | |

Provide 2 years warranty |

Packing:

Outer Packing---Wooden case

Inner Packing----Wrapped film.

Delivery : 20-40 working days

We have these Certificates: CE, GOST, TUV, Supplier Assessment

Q1. Are you a manufacturer or a trading company?