1. Our frying snack Food Extruder Manufacturers main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Fryer ,Dyer&Oven source can be designed use Electricity, Gas, Oil or stream.

6. Machine material generally is Food grade stainless steel, also can customized as require.

7. Guarantee Time is 2 year.

8. After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

9. Certificate: CE, SGS, BV

1. Our frying snack Food Extruder Manufacturers main motor brand is SIEMENS.

2. Relay: ABB or customized.

3. Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider.

4. All the electric device brand can be customized as you need.

5. Fryer ,Dyer&Oven source can be designed use Electricity, Gas, Oil or stream.

6. Machine material generally is Food grade stainless steel, also can customized as require.

7. Guarantee Time is 2 year.

8. After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

9. Certificate: CE, SGS, BV

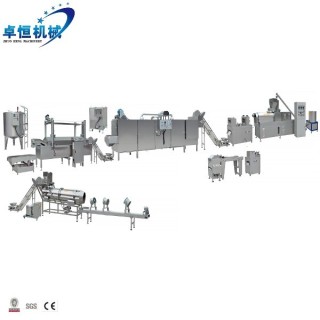

1.Core-filling food processing machine machine line uses advanced extrusion technology and achieve atomation from mixing ,extruion ,shaping,filling,drying,flavoring,cooling.

2.Snack food machine line can produce different shapes core-filling snack and puffed food by Chaning the molds.

3.This automatic process is of leading level for its superior characters"normal material,convenient operation and maintenance,lower powder consumption,higher output.

1.Our Industrial Automatic chocolate core filled snack making machine's main motor use the SIEMENS and the relay is ABB.

2.Converter(used to control the speed of feeding system,cutting system and control system,can protect of the motor)use the brand of Delta,Pioneer,CHNT or Schneider.

3.Oven &Dryer includes hot air cycle system,it has electricity,oil,steam,gas and it depends on your choice.

4.Certificate: CE, SGS, BV and we can provide the formula.

5.Guarantee time is 2 year.

6.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Hot Sale Fried Snack Food Processing Line Nachos Making Machine from China: The quail egg industry accounts for 40% of the national market. The rapid increase in production efficiency has reinvented the company and set a target of reaching an annual output value of 500 million yuan by 2020.

Kurkure chips snack food machine

The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knives can cut into required lengths. The Kurkure/Cheetos are fried in cooking oil or toasted in oven and then cooled before flavoring. Due to the delicious flavors and nutrition, it is quite popular with consumers.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dyer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.

Salad Chips making machine

It could make different shapes of fried snack food by changing shaping machines after extruder, such as bugle chips snack food, tortilla chips, fish shape and so on.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dyer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.

Puffed Rice Making Machine could make different shapes of puffed snack food by changing dies in extruder.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dyer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dryer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dryer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.

1.Extruder Main motor: Siemens China

2.Relay: ABB

3.converter:Delta,Pioneer,CHNT, Schneider or customize.

4.Dryer: hot air circulation system save cost & electric.

5.Machine material: stainless steel.

6.Guarantee Time: 2 year

7.We supply basic formula when you order our machines and send our engineer for installation trial run and training your workers

8.Certificate: CE, TUV,BV.